Spray-on Washi Project

1. Introduction

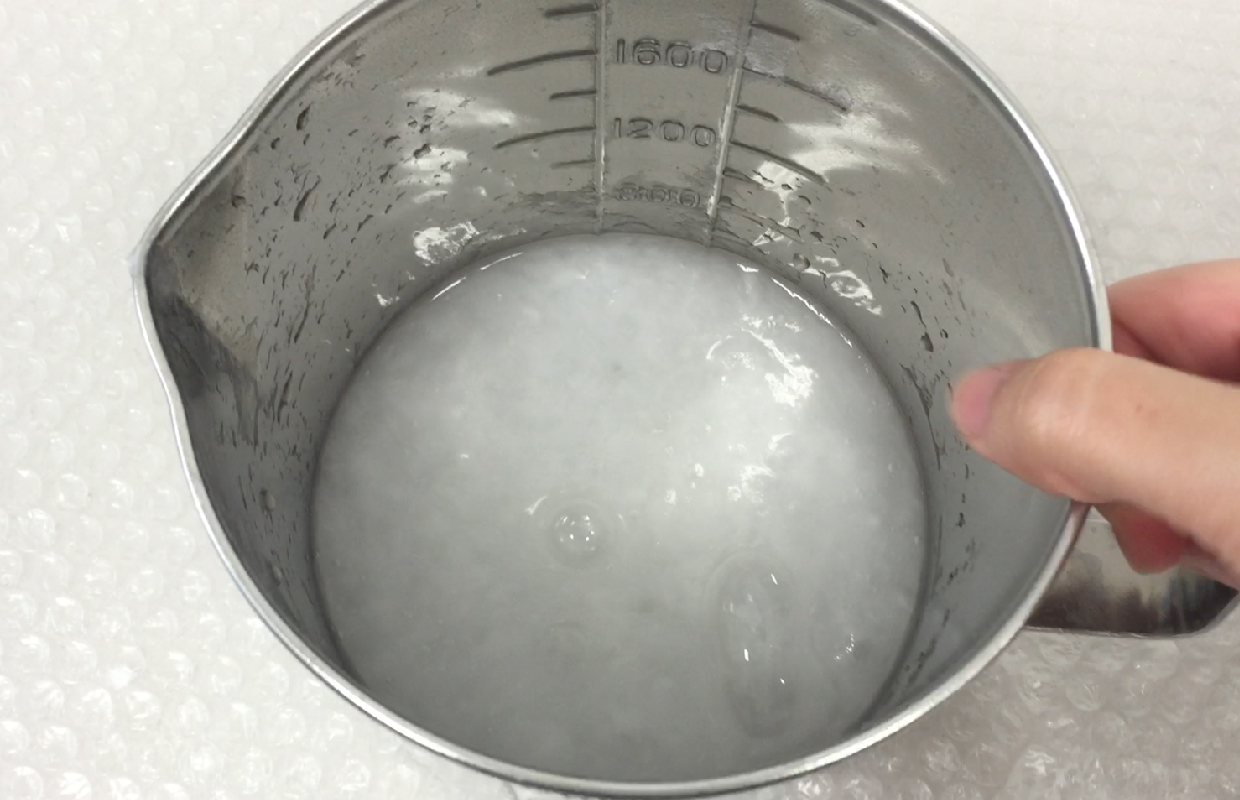

Spray-on washi is a new material made by exposing CMC gel to a kind of “radiation” (similar to what is used in the medical field), and adding the gel to the kozo or paper mulberry pulp used in the production of Japanese washi paper. The result is a stable washi spray. Using a spray gun, this material can be applied to a variety of objects to create a washi coating (Fig. 1). This material combines the characteristics of washi and the characteristics of spray-on application, making new effects possible.

To date, spray-on washi has mainly been used as a coating on the interior walls of buildings. Although there have been some examples of it being used to coat furniture and lighting fixtures, its use has remained relatively limited. Moreover, in almost all cases, it is being used to apply an even coating of washi, which fails to take full advantage of the unique attributes of the material.

2. Project Aim

Noting the current limited applications of spray-on washi, which have not fully utilized its special characteristics, the researchers conducted this project with the aim of creating new effects with the material.

Although research has been conducted on spray-on washi as a material, not much has been done to research its unique effects. If new effects could be developed using spray-on washi, new product applications could be discovered beyond interior finishes, currently the main use of spray-on washi.

3. Characteristics of Spray-on Washi

In order to explore greater potential effects of spray-on washi, the material was sprayed under various conditions. The results of these trials were used to divide the characteristics of spray-on washi into the following four categories.

3-1. It can be sprayed onto a variety of materials.

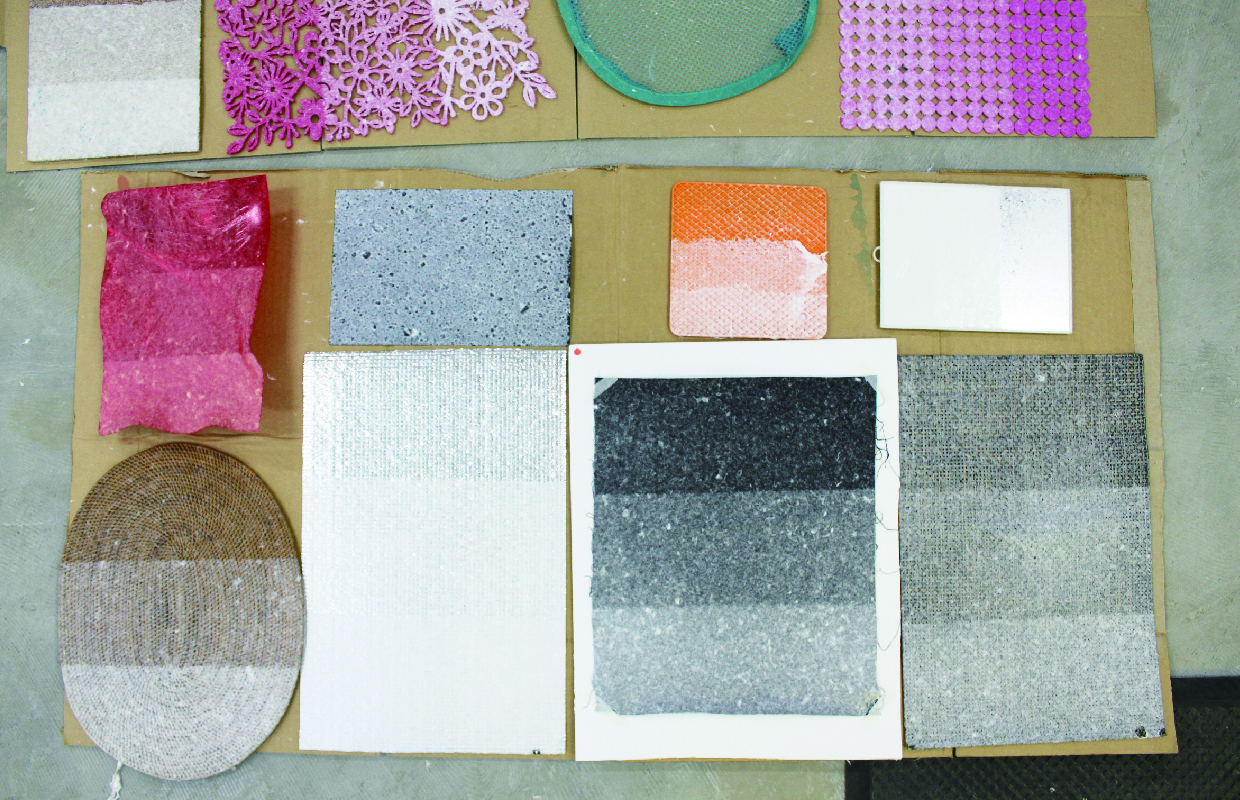

Spray-on washi was applied to samples of fabric, mesh, kiri (paulownia wood), plywood, aluminium, glass, rattan, ceramics, cellophane, silicon, polypropylene film, and cork. All were successful indicating that spray-on washi can be applied to a wide range of materials (Fig. 2).

However, the texture and hardness of the surface being sprayed affects adhesion strength. If a surface is hard and rough, the spray-on washi adheres relatively well, but on smooth, soft surfaces, the material peels away quite easily.

3-2. It can be sprayed onto a variety of shapes.

It can be sprayed on any form, flat or curved (Fig. 3).

3-3. A diversity of textures and colors can be achieved.

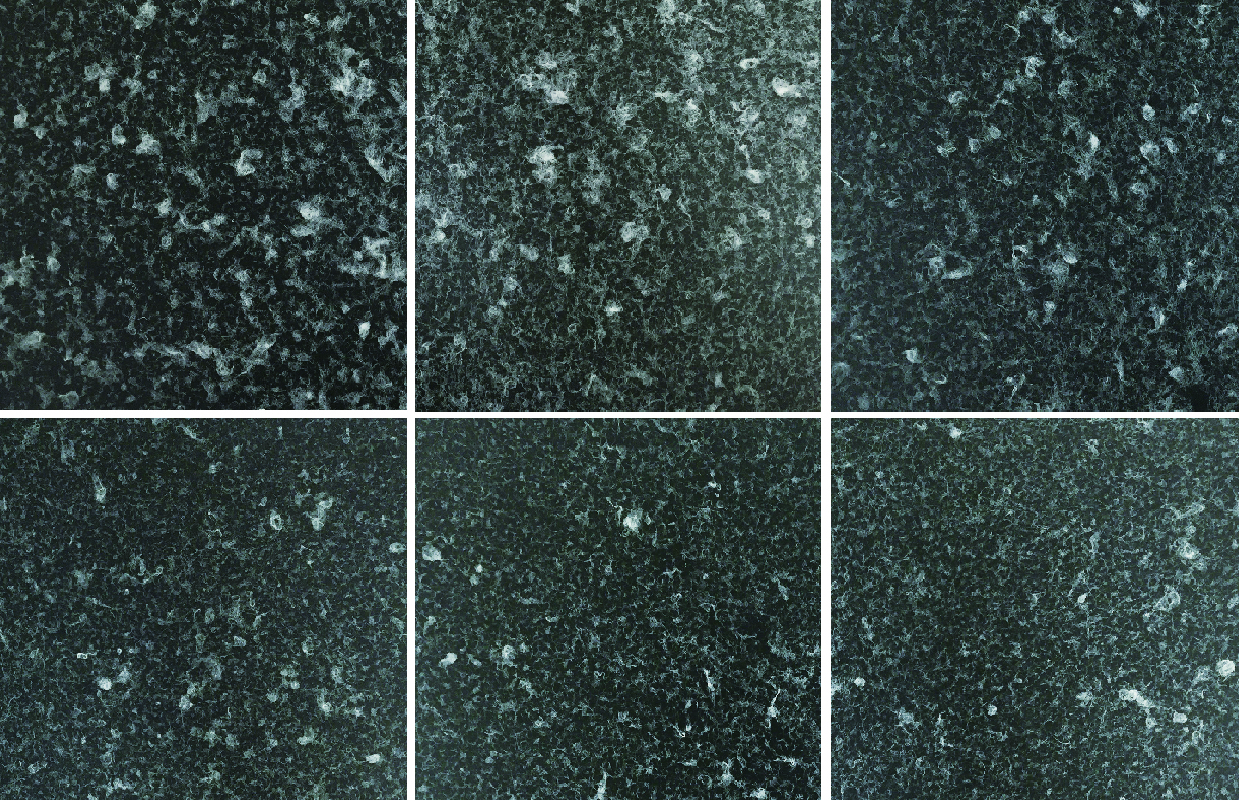

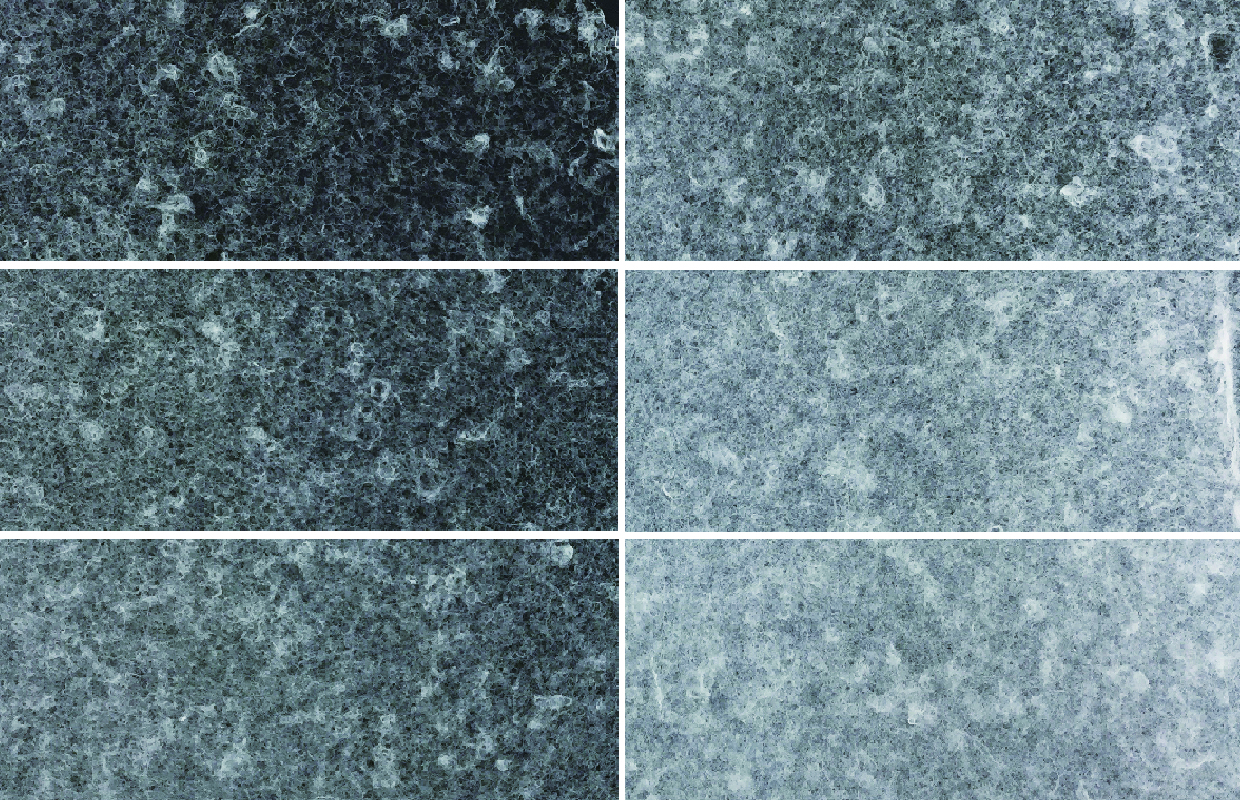

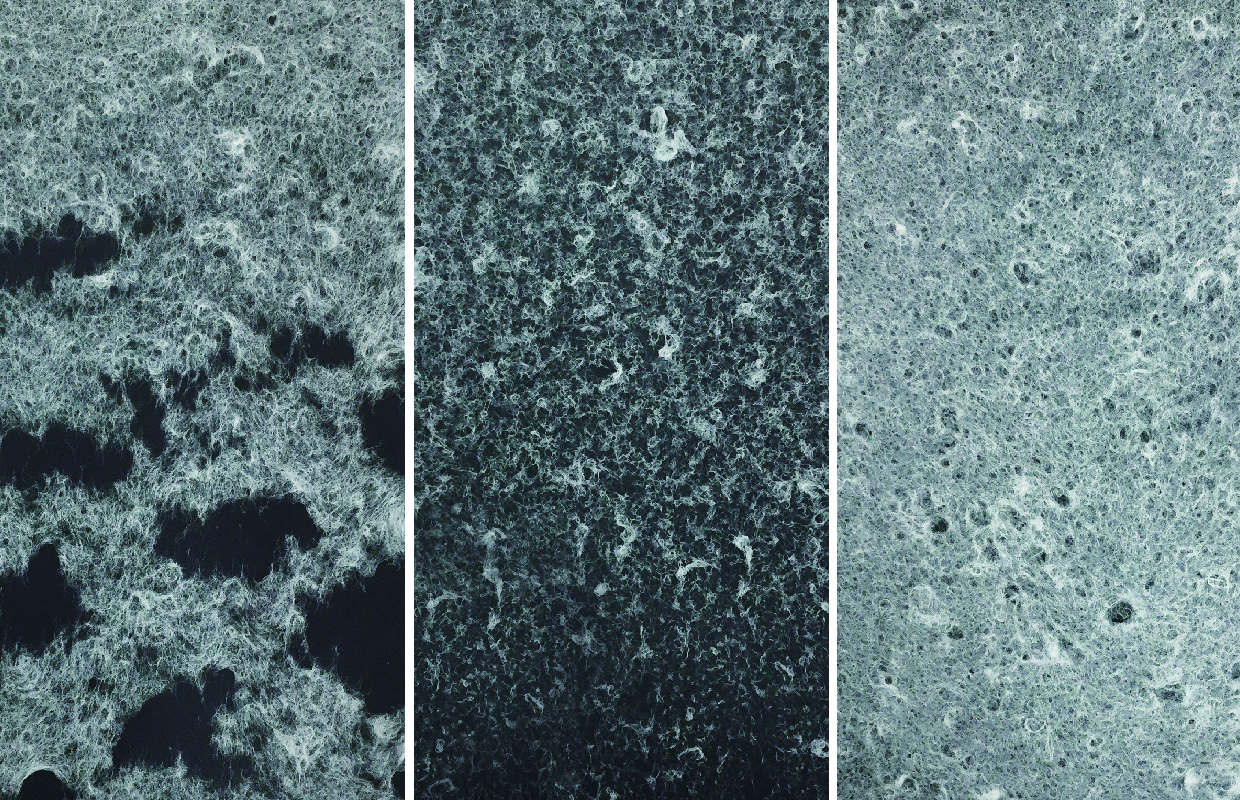

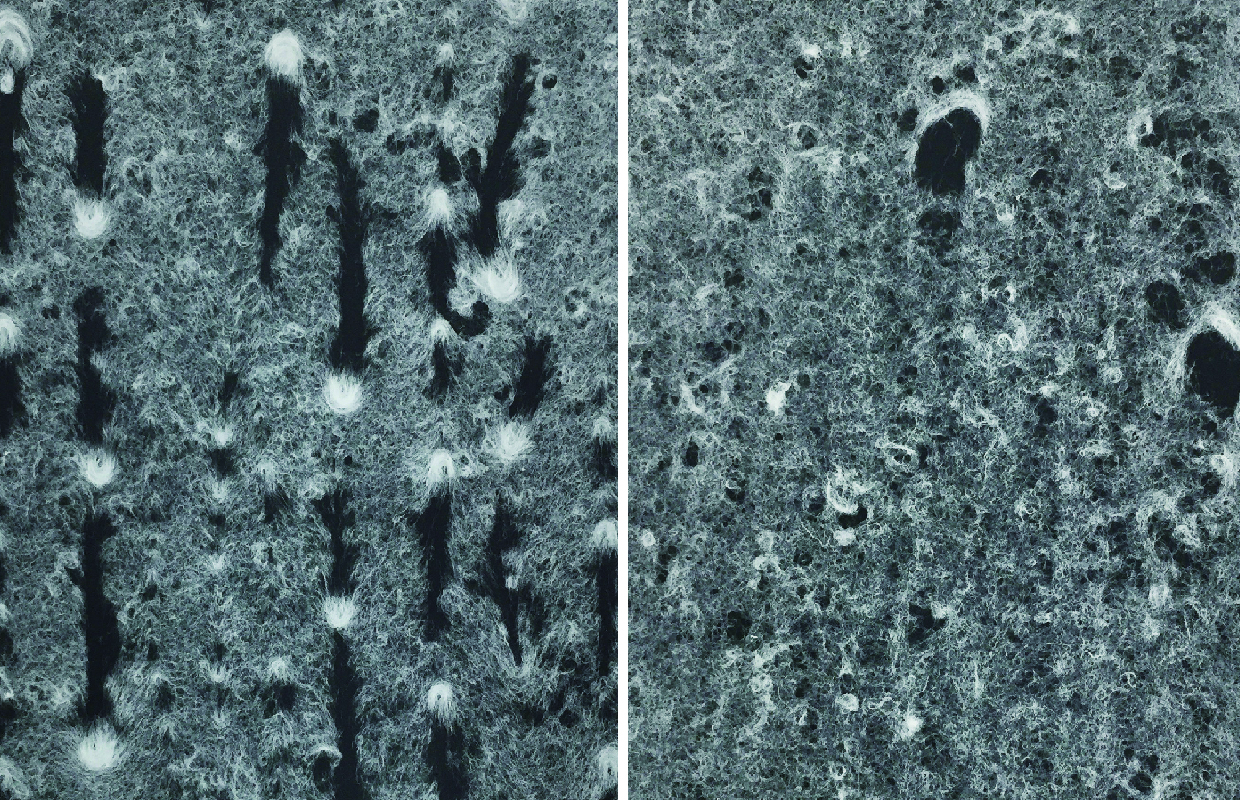

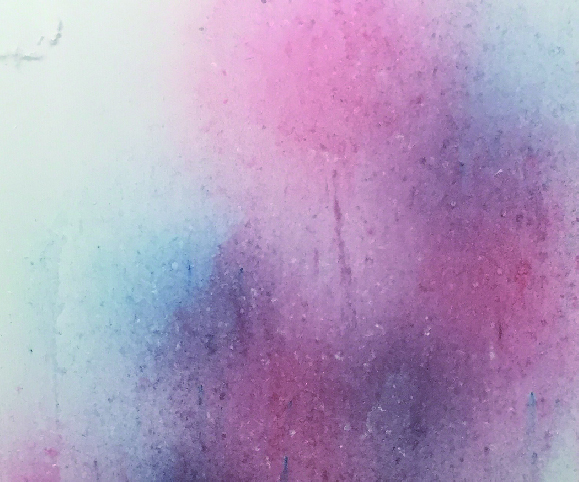

The appearance can be changed considerably with differences in spraying compressor pressure (Fig. 4), the number of coats (Fig. 5), the way in which it is sprayed (Fig. 6), and post-spray treatment (Fig. 7). The material can also be colored. (Fig. 8).

※Fig.4

※Fig.4  ※Fig.5

※Fig.5  ※Fig.6

※Fig.6  ※Fig.7

※Fig.7  ※Fig.8

※Fig.8

3-4. The washi itself can be made three-dimensional.

It can be removed from a mould and allowed to stand on its own.

4. Methodology

By combining the different characteristics of spray-on washi described in 3. above, it is possible to create effects that are unique to the material. In this research project, from the range of effects that could be achieved through combinations of these characteristics, the following four methods, which have freater creative potential, were selected and prototypes were made.

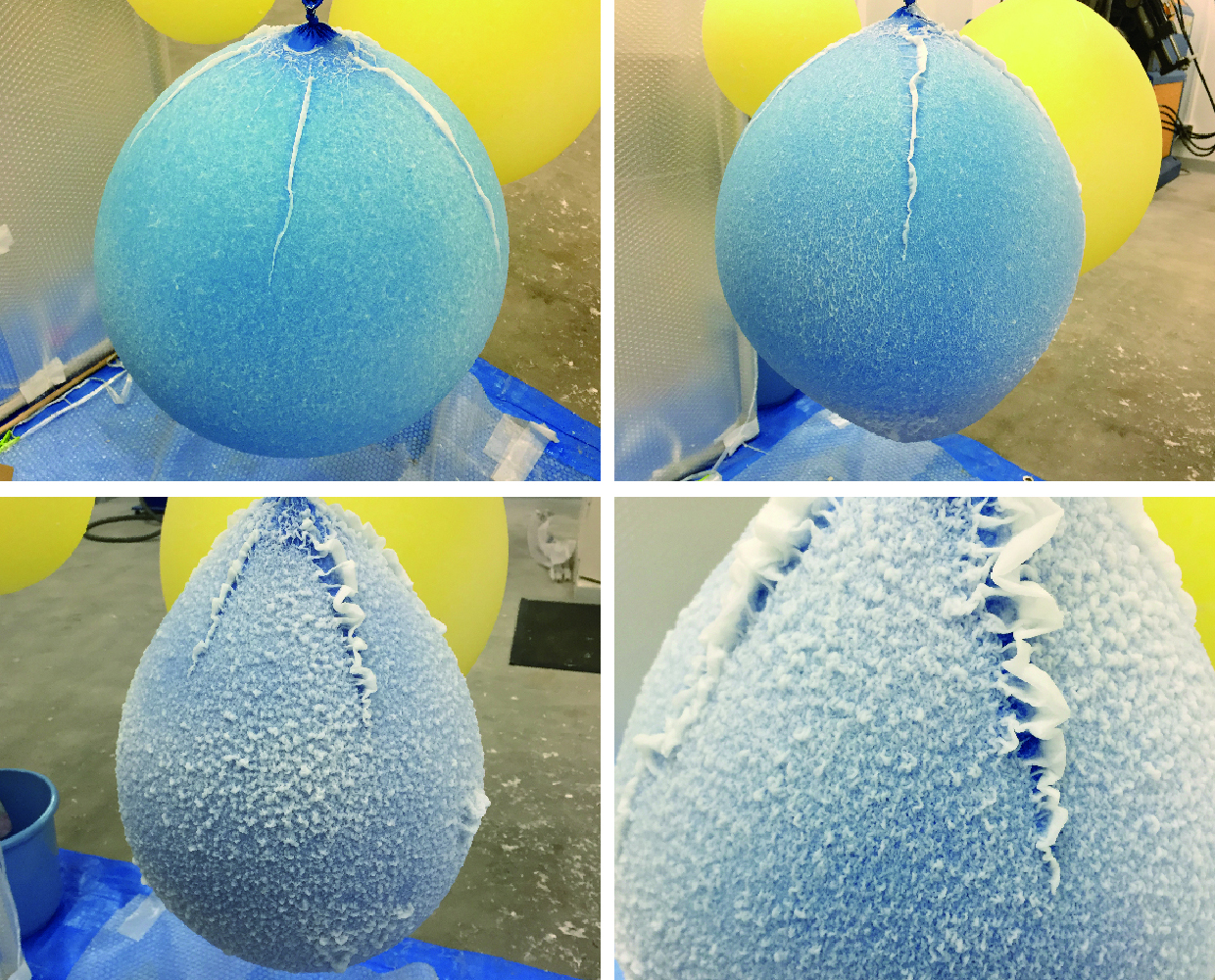

4-1. Balloon spraying creates wrinkles

Taking advantage of the ability to apply spray-on washi onto a variety of materials and onto a variety of shapes, the material was sprayed onto a balloon in several layers. The air was let out of the balloon, and when it was removed, a material with a finely wrinkled texture resulted (Fig. 9).

4-2. Fabric-covered balloon spraying creates wrinkles

A bag made of a stretchy fabric was placed over a balloon and the material was sprayed onto the bag in the same way as in 4-1. The air was let out of the balloon, and a material that retained the shape of the fabric was created, with wrinkles similar to those in 4-1 (Fig. 10).

4-3. Spraying for a gradation effect

Combining the diversity of texture and color effects that can be achieved with spray-on washi with its ability to stand alone can effectively produce three-dimensional graphic expressions.

4-4. Spraying onto ceramic material

Considering that it would be effective to take simple advantage of the ability to apply spray-on washi’s onto various materials and shapes, the researchers sprayed it onto a rough ceramic base. The rough surface provided optimum adherence and spray-on washi could be used in place of a glaze.

5. Work Produced

Five samples were produced using these four methods.

As examples of 4-1, a pouch (Fig. 11) and soft toy (Fig. 12) were produced, and the material obtained from 4-2 was made into a tote bag (Fig. 13). For 4-3, a kind of bowl was made (Fig. 14), and a vase was produced to demonstrate 4-4 (Fig. 15).

※Fig.11

※Fig.11  ※Fig.12

※Fig.12  ※Fig.13

※Fig.13  ※Fig.14

※Fig.14  ※Fig.15

※Fig.15

6. Future Outlook

Researchers made a range of products in which the washi texture could be appreciated, with a focus on conveying the new effects from spray-on washi, the aim of this project. These techniques can be adapted for use on a variety of decorative and practical items for the home, lighting fixtures and more. The material is easily colored, making possible a wide range of colors and tones (Fig. 16).

This research project has demonstrated that spray-on washi, which is currently used predominantly for building interiors, can be used to produce unique effects, and that it is possible to adapt it for use in a variety of products.

※Fig.1

※Fig.1 ※Fig.2

※Fig.2 ※Fig.3

※Fig.3 ※Fig.9

※Fig.9 ※Fig.10

※Fig.10 ※Fig.16

※Fig.16